Bottling Day Afternoon

In our last installment, I brewed a Belgian Witbier like a Belgian boss and have been patiently waiting while the Belgian yeast converts that sweet Belgian sugar into some tasty, drinkable Belgian (style) beer. I bought all the ingredients in Montgomeryville, PA so I don’t know how Belgian any of this stuff really is. We’ll soon find out how Belgian it actually tastes, which is all that really matters.

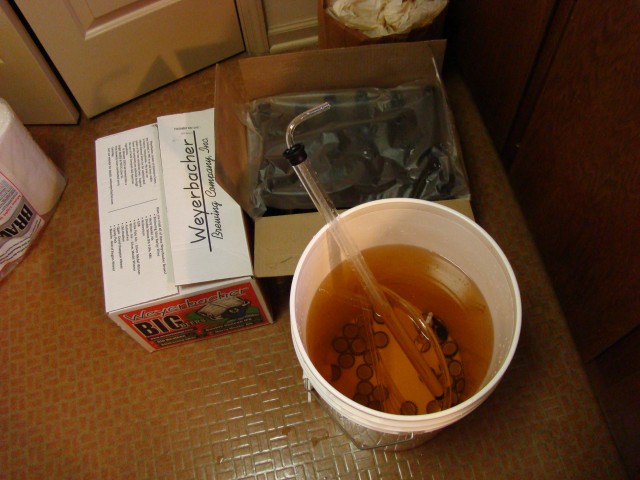

Before I can start drinking this stuff, though, I have to get it into bottles for a little “conditioning” action. Apparently waiting until the fermenting is finished isn’t enough. The fermented wort must now be transferred to a bottling bucket (which was actually way easier than you would think since they make this thing called an auto-siphon that does all the work for you), mixed with 5 oz of priming sugar (which I had earlier dissolved in 2 cups of boiling water which, when cooled down, was added to the bottling bucket before auto-siphoning the wort) and transferred again into cleaned and sanitized 12oz brown beer bottles using the way-cooler-than-it-looks bottle filler attachment that attaches to a length of rubber tubing that attaches to the spigot near the bottom of the bottling bucket.

My lovely girlfriend and sometimes partner in beer making, Anna, took control of the bottle capper, hermetically sealing away our fine brew with sanitized bottle caps, trapping the additional CO2 that will be created thanks to the priming sugar added just before bottling, which will give the beer its carbonation. Over the next several weeks (at room temperature) the beer’s flavor will continue to develop, while I continue to not drink it.

Photos

Sanitized bottles and bottling equipment

Fermenting bucket, on the counter

I had a misfire on my 3rd attempt, after which Anna took over and did the rest of them with no issues.

Now I get to stare at this for a while.

A Quick Taste

Through the magic of the internet, we will now flash forward to 1 week after bottling, in which Anna and I chill one of the beers, pry off the cap (it sounds carbonated!) and pour a test glass. It looks like I would expect — a cloudy amber color with a small amount of white head — but the carbonation seems a little strong already which I’m assuming means the fermentation wasn’t 100% finished before bottling.

I forgot to mention that I finally figured out how to take a gravity reading after the wort was in the bottling bucket. By then I was sort of committed to bottling but wanted to see what the final gravity was. According to the recipe, it should have ended up at 1.014 but I was getting 1.020. The original gravity was somewhere around 1.045 so the number is supposed to be going down and the fact that it was still above 1.014 obviously means that it wasn’t there yet. What that ultimately means, I have no idea, other than the fact that I might end up with a slightly higher ABV than originally expected.

As for the taste, it was a little underwhelming. There wasn’t anything wrong with it, just a little bland I guess. I’ve seen people refer to a beer tasting “green” when tasting during the conditioning period, so maybe that’s what’s going on. I’m not sure what “green” tastes like. Hopefully another week or two in the bottles will help. According to everything I’ve read, it will. If not, it’s nothing a few extra orange slices won’t fix.

This weekend will be two weeks since bottling so I’ll try another one and see where it’s at. What I’m more excited about though is what’s next, whatever that is, when I start brewing another one on Sunday (any suggestions for what I should do next?)